CGMP Validation Services

We provide cost-effective CGMP commissioning and qualification services for 503B, Cell & Gene, and traditional pharmaceutical manufacturing facilities. Our engineers have deep expertise in developing and implementing validation protocols (IQ, OQ, PQ), as well as preparing compliance documentation for equipment, utilities, processes, lab instruments, and computerized systems.

Commissioning, Qualification, Validation

Equipment | Utilities | Lab Instruments | Computer Systems

Refrigerators, Freezers, Incubators, Stability Chambers

Depyrogenation Ovens

Autoclaves

Blenders, Mixers, Agitators

Tablet Presses & Encapsulators

PECs (e.g., LAFW, BSC, RABS, Isolators, Powder Hoods)

Filtration Systems

Glassware, Parts Washers

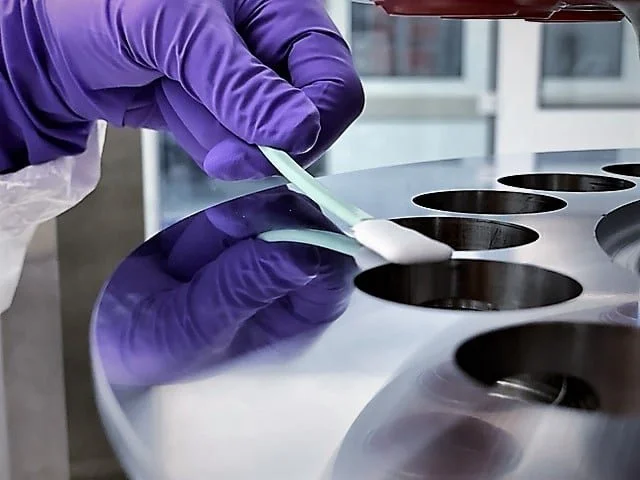

Aseptic Processing Equipment

Capping Equipment

Inspection Systems

Label & Packaging Equipment

Water Systems (e.g., Water Chillers, PW, WFI)

Compressed Air & Gas Systems

HVAC Systems

Clean-In-Place Systems

Steam/Sterilize-In-Place Systems

Environmental Baseline Studies (EMPQ)

GC & HPLC Instruments

Weighing and Dispensing Systems

Laboratory Information Management Systems

Computer Systems

And More

We support facilities with risk-based, inspection-defensible CQV strategies that align with FDA and state expectations while avoiding unnecessary validation burden. Our approach integrates facility design, equipment qualification, process risk, and lifecycle management — not just protocol execution.

How Clients Use Us

CQV strategy & scoping before validation begins

Fractional CQV leadership during build-out, expansion, or routine requalification periods

Design, execution and report writing of CQV programs

FDA inspection preparation and remediation